The art of bespoke fulfillment solutions

An interview with Anna Zajdzińska, Senior Solution Design Engineer

Success in e-commerce fulfillment lies in the ability to understand and address each business’s unique challenges. The key is not just on solving today’s logistics problems, but creating flexible solutions that support long-term growth and scale with the business.

In this interview, Senior Solution Design Engineer Anna Zajdzinska, shares insights into the art of creating bespoke fulfillment solutions.

With over 14 years of experience in logistics and project management, she specializes in developing customized automation solutions that help e-commerce businesses thrive in a very competitive market.

Through examples ranging from fashion brands requiring unique promotional capabilities to health and beauty companies needing specialized handling, Anna demonstrates how technical expertise combined with creative problem-solving can turn logistics challenges into opportunities.

From civil engineering to logistics

Q: How did you find your way into solutions engineering in logistics?

A: I originally studied civil engineering, but my first job after graduation was in logistics. I worked for a racking company called Stow for several years before joining Radial. While I initially was looking for a project manager role at Radial, I found myself in the solution design department and really enjoyed it from the start.

Q: How does your civil engineering background contribute to your current role?

A: Although I studied civil engineering and enjoyed it, I discovered my passion for logistics in my first job. The analytical and problem-solving skills from my engineering background have proved valuable in solutions engineering, where we need to think systematically and creatively to solve complex logistics challenges.

The art of tailoring fulfillment solutions

Q: What makes Solutions Engineering at Radial unique?

A: We don’t work with standard templates for customers. Instead, we customize everything by diving deep into the customer’s business to identify their pain points and find ways to solve them.

The most challenging part is getting customers to share those specific aspects of their business that they might see as typical, but are actually crucial from a logistics standpoint.

When we dig into these details, we often discover elements that are critical for the whole process and need to be carefully incorporated into our solution.

Q: Can you share an example of a creative solution you developed?

A: One of my first successful projects was with a fashion industry client. They wanted to clear their warehouse of previous season’s designs through a special promotion where customers would receive “random” products at a special price.

This was challenging because in logistics, there’s no such thing as a “random” product – everything needs to be specifically selected and tracked. We had to develop a system that could deliver different products while ensuring that when a customer ordered multiple items, they wouldn’t receive duplicates.

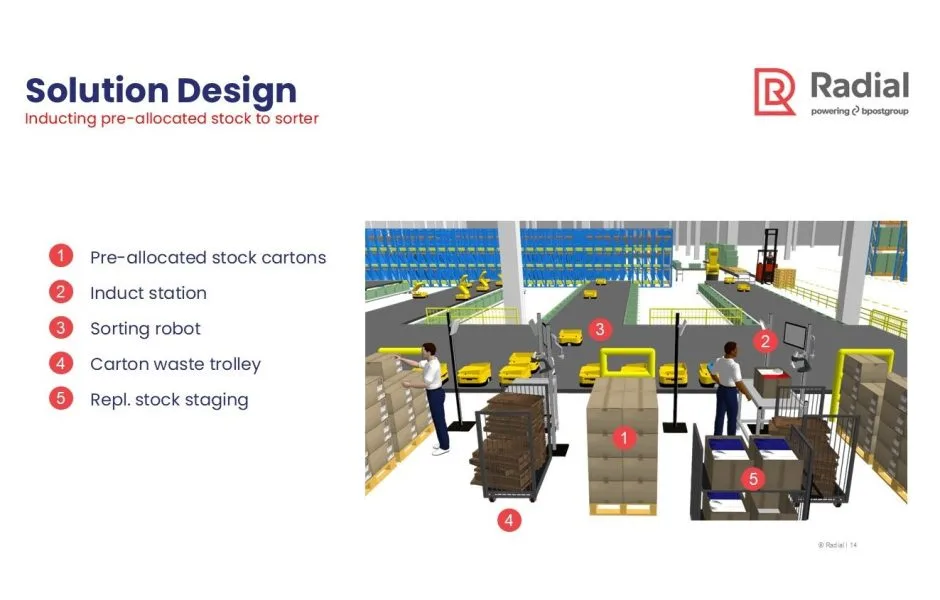

3D visualizations of a fulfilment solutions helps our customers to look into future of logistics.

Industry challenges: insights from key sectors

Q: What industries do you primarily work with?

A: At Radial, we primarily work with health and beauty cosmetics and fashion brands. We’ve also started working with DIY and food providers. Each industry has its own unique requirements and challenges that we need to address in our fulfillment solutions.

Q: What’s your specialization within the solutions engineering team?

A: Our team is a great mixture of different personalities with unique set of skills. We have several solutions engineers like Martine, Szymon, Scott and Geovanny, pricing managers: Caio and Patryk and Bert as our team leader.

Within this team, we have different specializations. For instance, Martine and I focus more on automation solutions and work closely with our partners in the robotics field. I’m also the most experienced team member with drawing package which includes both 2D and 3D software. We use those tools to create new solutions and templates that can be reused for future customer processes. This helps us build a library of solutions that can be adapted for new clients.

Radial Poland serves over 70% of doTERRA’s customers across the European region.

Automation, scalability, and the human touch

Q: How do you approach the choice between manual, semi-automated, and fully automated solutions?

A: We tailor our approach for each customer. While we recognize that automation is the future, we don’t treat it as a universal solution. Investment costs need to balance with future profits, so we carefully investigate each customer’s operation to determine if automation would truly bring improvements. Sometimes, a smart manual solution brings the most benefit.

For growing customers, we regularly revisit their operations – monthly, quarterly, or annually – to assess if new automation investments make sense as their business evolves.

Q: What’s your view on full automation versus mixed solutions in e-commerce logistics?

A: From our experience, the best approach is a balanced one. While automation can significantly boost productivity in specific areas where it’s truly needed, the human touch will remain essential for a long time to come.

This aligns with recent industry analysis suggesting that mixed solutions – combining people and machines – offer the most flexible and scalable approach for e-commerce logistics.

Complete automation often hits scalability limits depending on the industry, brand, and product type. The key is finding the right mixture of automation and human involvement to create the most effective solution.

The autonomous mobile robots (AMRs) transport pallets and totes between transfer and picking stations at this Radial site.

Creativity over AI

Q: What’s your experience with AI tools in solutions engineering?

A: I’m actually quite old-fashioned in my approach. I rely mainly on my own creative work rather than AI tools. At this point, I haven’t integrated AI significantly into my daily work or solution development process.

What drives Anna in her role

Q: What’s most rewarding about your role?

A: I particularly enjoy the direct contact with customers, which gives me very positive energy. It’s rewarding to see how our creative fulfillment solutions can solve real business challenges. Also, being specialized in automation solutions and robotics allows me to work on cutting-edge projects that are shaping the future of logistics.

Q: How do you handle work-life balance with Radial’s remote work policy?

A: I have the perfect balance. I live 50 kilometers from our warehouse, which I visit weekly. I also travel to different sites in Europe once every month or two months to meet with potential customers or show them our facilities.

The rest of the time, I work from my home office, which is especially valuable as a mother of two small children. It allows me to be immediately available for them when I finish work or handle any urgent needs during the day.

Poland as a logistics powerhouse

Q: As someone working in Poland’s logistics sector, how do you view the country’s economic growth?

A: I’m very happy about Poland’s good results. Our people are hard workers, and we’re starting to see the benefits of that effort. We’re increasingly recognized as professionals in Europe, and more businesses are choosing to place their logistics operations in Polish warehouses.

As a society, we’re adapting well to this growth, particularly through investments in education. It’s really a positive change for Poland.

The installation of a solution designed by Anna for one of Radial’s clients in Poland.

Ecommerce, up close and personal

Q: What’s your perspective on e-commerce as both a solutions engineer and a consumer?

A: As a consumer, I’m a huge e-commerce user! I prefer online shopping over traditional retail because it’s more time-efficient. I find traditional shopping stressful, especially when looking for specific items.

Online shopping makes it much easier to filter options by color, size, and type, helping me find exactly what I need. This personal experience also helps inform my work in creating fulfillment solutions for e-commerce businesses.

Anna Zajdzińska is a Senior Solution Design Engineer at Radial Europe with over 14 years of experience in logistics and project engineering. Following her Master’s in Civil Engineering, she built her career through an 11-year tenure at stow Group, where she developed expertise in project engineering, product specialization, and technical consulting for key accounts.

Since 2022, she has been with Radial Europe, focusing on automation and robotics for ecommerce fulfillment solutions across Europe.

Certified in both AgilePM® Foundation and Professional Scrum Master™ I, Anna’s approach emphasizes continuous improvement and client-focused solutions.

Based in Warsaw, she has a flexible work arrangement that combines on-site visits with remote work.