Realize Significant Cost Savings with Radial Package Engineering

Ecommerce businesses are under pressure to reduce costs and maximize margins – without jeopardizing customer experience. One way to do this is through package engineering – where design experts help you rethink your packaging, taking into consideration sustainability, right-sizing, transportation impact, branding, and the unboxing customer experience.

An even bigger way to do this is by bundling package engineering with fulfillment and transportation management with an experienced 3PL that offers these services. Radial has been supporting eCommerce businesses with tailored services for 30 years; navigating and thriving through numerous economic downturns and change. Longevity in the 3PL industry gives us an upper hand when it comes to relationships with shippers, carriers, suppliers, and customer experience designers.

If you’re looking for a way to cut costs, improve transportation efficiency, hit sustainability goals, and create an exceptional unboxing experience – consider the advantages of package engineering.

Why Do You Need Package Engineering?

We’ve all had a small item we’ve ordered show up in a huge box and thought: why didn’t they use a smaller box? Packaging becomes the customer’s problem once they receive it – and an aspect of the customer experience that few talk about. Customers assume the brand they ordered from chose the packaging, so creating a negative (if not annoying) problem by sending a customer the wrong-sized or ineffective package impacts brand reputation. You don’t want your customers to ever have any negative thoughts about you – even fleeting ones around wrong-sized boxes.

The packaging matters.

When a customer experiences a damaged order because the packaging was deficient, they feel disappointed and unvalued.

Choosing right-sized packaging, made from the most efficient and effective materials helps ensure better inventory management, storage, shipping efficiency, protection during transit, and reduces waste. Eco-friendly, recyclable materials and customized branding touting your ESG values support sustainability goals. It also creates an intentionally positive unboxing experience that feels personable and delightful.

Many eCommerce brands waste money by failing to intentionally engineer their packaging to be more effective, efficient, and eco-friendly. Or they partner with 3PLs that do not offer this expertise and support.

The advantages to the retailer, shipper, customer, and environment are too great to ignore.

Brands can hire their own packaging engineer teams to design, develop, and test packaging – but this requires significant budget. At Radial, we bring this value-added service to retailers as part of our tailored service approach. Our Package Engineering department works with a team of industry and supplier experts to collaborate on designing, developing, testing, certifying, manufacturing, and optimizing sustainable packaging customized to your products and brand.

Radial customers save substantial costs when they engineer their packaging.

Rethinking Packaging to Reduce Costs

At Radial, we don’t believe in cookie cutter approaches. While there are similarities among eCommerce retailers, no two are the same. Neither are their packaging needs. Yet, too many in the industry approach packaging as a one-size-fits-all (no pun intended). There is often value and cost savings to be uncovered when you rethink your packaging content, design, materials, style, and branding.

In fact, one of our favorite things to do is investigate the cost and environmental impact of redesigning packaging. Sometimes switching to a different material can make a big difference.

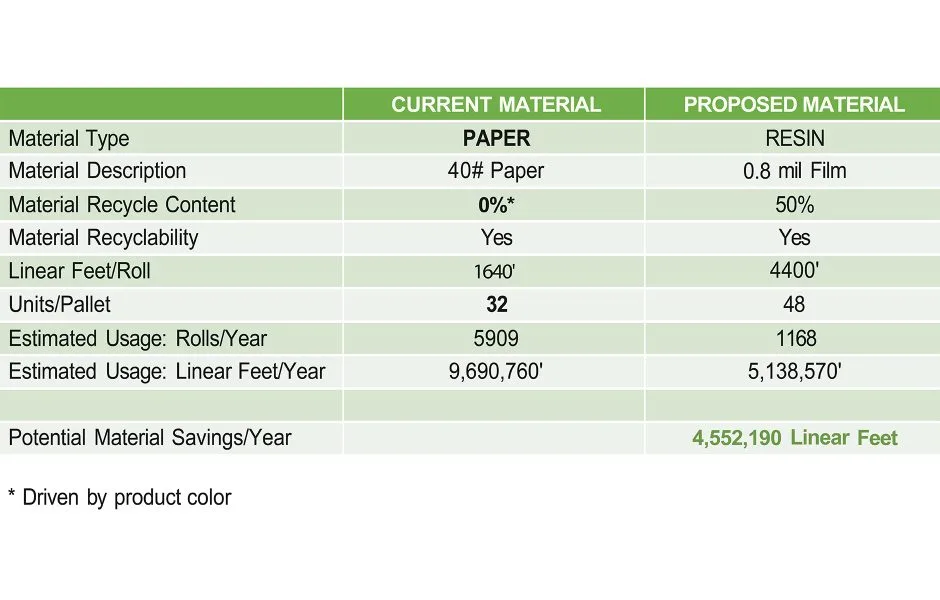

That switch is not always intuitive. Take for example, one Radial customer that was using paper-based dunnage to fill voids and keep products safe during transit. People assume paper is the most eco-friendly option, but in this situation, we discovered that by switching to inflatable resin-based film, the customer would actually increase their sustainability impact and experience significant material savings per year.

Both the paper and the inflatable film offer superior void fill, come in reduced footprint format, and are created mechanically with custom equipment that provides efficient shipping and storage benefits.

But the inflatable film reduces material usage and its increased units per roll reduce transportation emissions which makes it a more sustainable option. The recycled content of inflatable film is 50% compared to colored paper that had 0% recycled content.

Here’s a breakdown:

This one switch enabled this retailer to reduce material usage by nearly half. These are the kinds of analysis and insights that we look for and identity for eCommerce companies.

How to Reduce Packaging Costs & Improve Sustainability

Here are some of the additional ways we can support you:

- Eliminating non-recyclable materials. One company was using a bubble mailer with a low (10-15%) amount of recycled material, with a lamination that was non-recyclable. We investigated alternate mailers and found a paper-based mailer that is curbside recyclable. By switching to this material, the company diverted 1.3M grams of material from the waste stream within a few months.

- Increasing recyclable content. By switching from standard corrugate that contains 30-70% recycled content to 100% recycled content that is FSC certified, the company saves energy by utilizing local sources of recycled material instead of virgin materials.

- Sourcing FSB certified materials. Upon request, we source FSC certified materials that support ethical, sustainable forestry standards that impact communities worldwide.

- Moving branding inside to thwart porch pirates. Many brands no longer want to make the exterior of packaging brand-recognizable to mitigate theft. We support brands by offering alternate graphic options, such as branded dunnage and interior package graphics, that deliver an unexpected and impactful unboxing experience.

- Auditing package sizing. It’s important to understand how to right-size packaging. We conduct right-size packaging audits to identify where improvements and cost savings can be made.

There are cost savings to be realized by engineering packaging and continually evaluating its effectiveness and validity. You can improve your customer experience and drive toward sustainability goals by becoming intentional about packaging.

Radial is here to support you in this.

Contact us to learn how we can help you reduce costs.